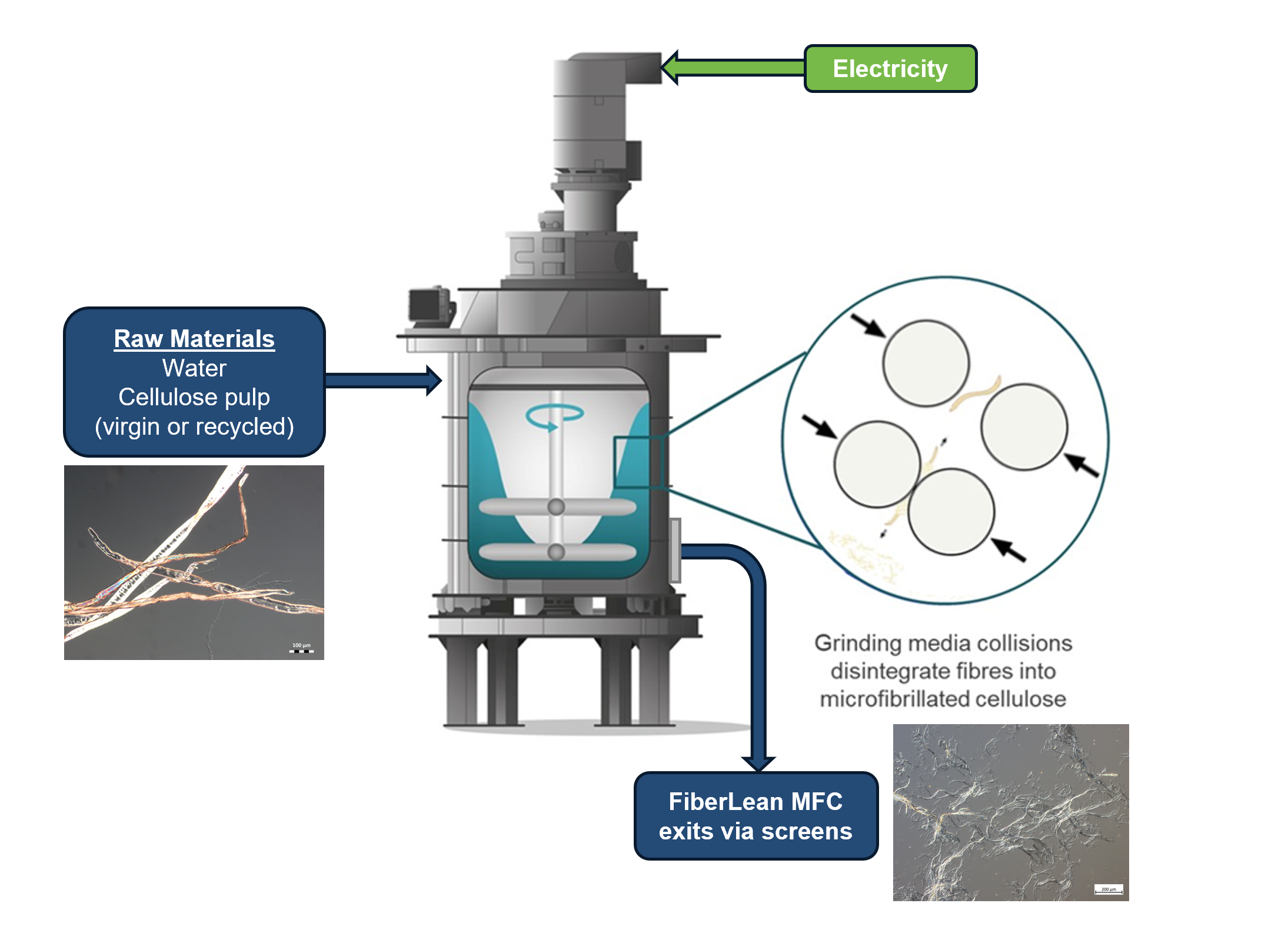

FiberLean Grinding Process

The FiberLean process uses Stirred Media Mills to produce microfibrillated cellulose (MFC). This technology was originally developed for the mining and minerals processing industry for particle size reduction, before being adapted by FiberLean for MFC production.

A stirred media mill is essentially a fortified stirred vessel, which is filled with ceramic grinding media beads. When the fibre suspension is added to the mill, the impeller imparts momentum to the grinding media, which collide with each other and break down fibres caught between them.

Compared to alternative mechanical MFC production methods, stirred media milling tends to generate a high level of fibrillation whilst minimising damage to the microfibrils; this results in the maintenance of relatively long fibril lengths and a higher effective aspect ratio, which leads to improved bridging and network-forming capability.

MFC morphology and characteristics can be optimised for the target application and for the feed fibres being processed by changing grinding media properties, impeller speed, solids content, and flow patterns. It is possible to vary media collision energies over several orders of magnitude whilst maintaining capacity, which permits high quality MFC production even from very weak fibres.